- Email Address

- Phone Number

+ 91 20 27290014 / +91 8956931329

ALUCAST Past Training Programs

Management for Success

Speaker : Mr. Vishwas Kale, MD - Vijayesh Instruments Pvt Ltd

Date : Friday, 17th October 2025

Time : 04:00 PM to 05:00 PM IST

Platform : Microsoft Teams

Key Takeaways

- Gain practical insights on applying management tools beyond theory.

- Learn from an entrepreneur's journey, including both successes and failures.

- Understand how concepts like Quality, Leadership, and AI can be applied in real-world scenarios.

- Motivation to achieve success through experience, adaptability, and continuous learning.

Industry Study Visit to Jaya Hind Industries (Urse Plant) & Aakar Foundry Pvt. Ltd., Pune

Date : Monday, 29th September 2025

Objectives of the Visit

- Facilitate knowledge sharing among member companies.

- Enable participants to observe real-time operations and benchmark against best practices.

- Provide insights into safety, productivity, and sustainability initiatives.

- Strengthen professional networking and collaboration within the industry.

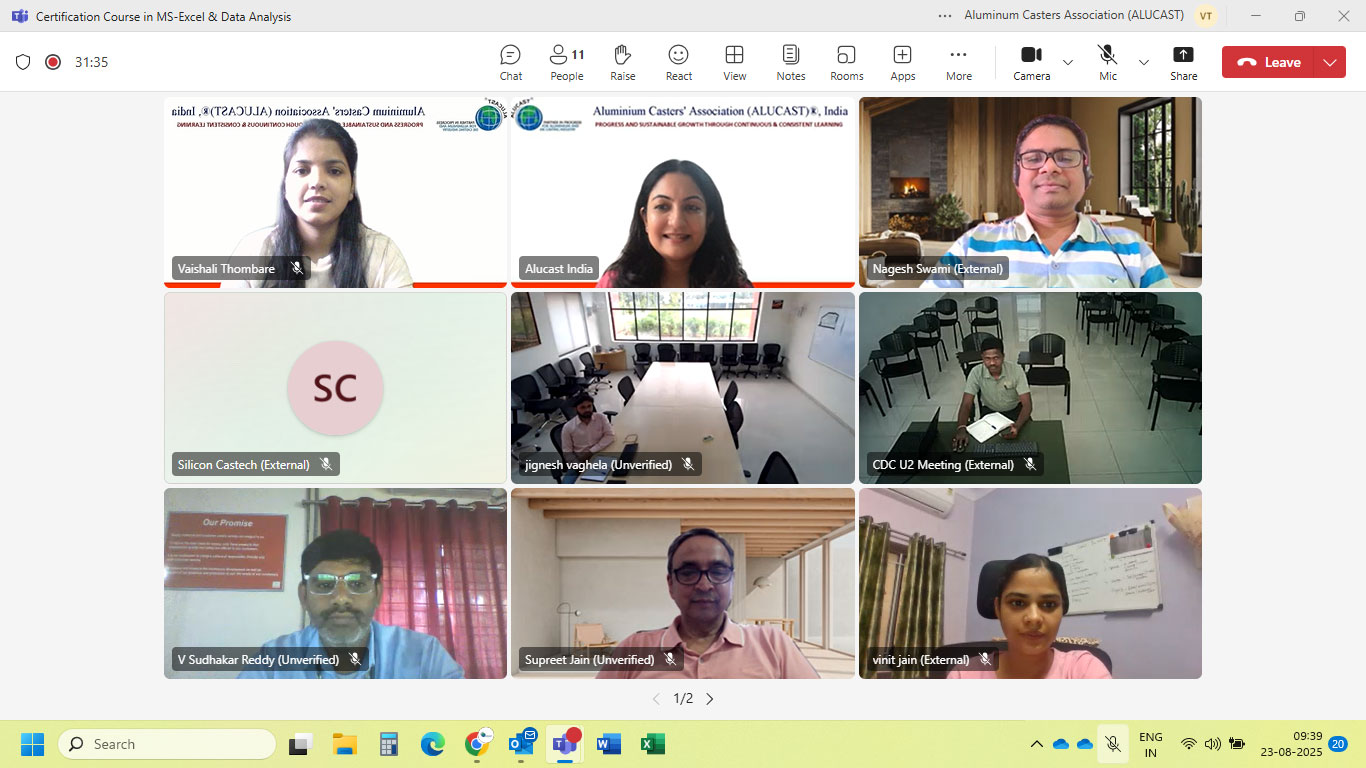

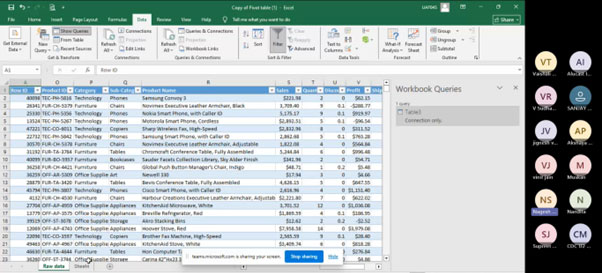

Certification Course in MS Excel & Data Analysis

Trainer : Mr. Nagesh Swami - Advanced Excel & Power BI Trainer with 15+ years of experience

Date : Saturday & Sunday, 23rd & 24th August 2025

Time : 09:30 AM to 01:30 PM

Platform : Microsoft Teams

Course Content

- Excel Foundations Refresher

- Advanced Formulas & Functions

- Data Cleaning & Preparation

- Data Analysis Tools

- Dashboards & Reporting

- Automation with Excel

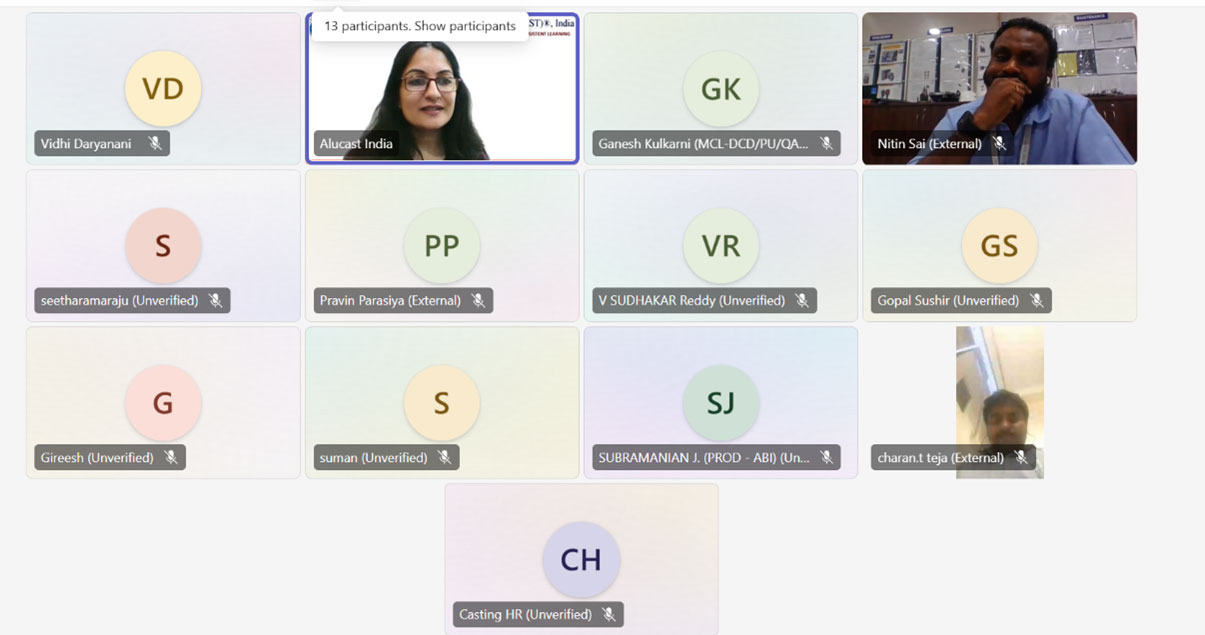

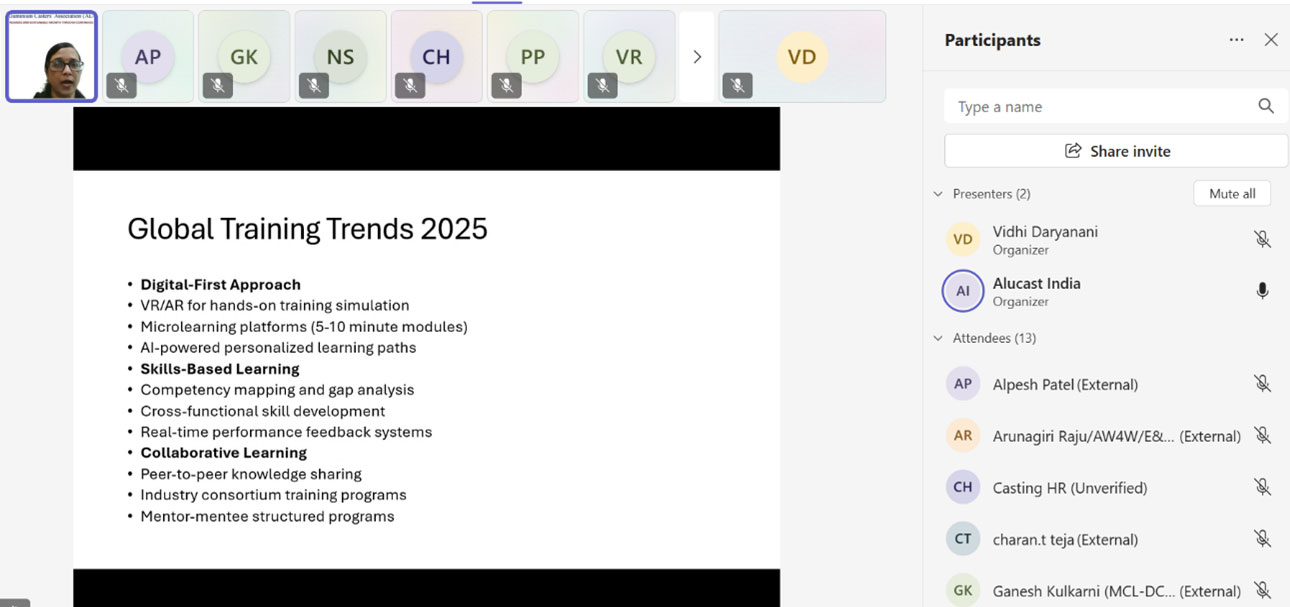

From LEARNING to IMPACT – Workforce Transformation

Date : Wednesday, 20th August 2025

Speaker : Ms. Sarika Joshi – Certified Auditor, Consultant, Facilitator & Trainer

Time : 06:00 PM – 07:00 PM IST

Place : Microsoft Teams

Key discussion points

- The role of training in driving business impact

- Identifying the right learning needs and topics

- Effective processes to plan and execute training

- Real-world best practices that deliver results

Cost Management in Diecasting (Exclusively for Jaya Hind Industries Team)

Date : Thursday, 07th August 2025

Speaker : Mr. G. Praburam, Managing Director – Alubee Die Casters, Honorary Secretary – ALUCAST Bangalore Zonal Centre

Time : 03:30 PM – 05:00 PM IST

Duration : 1 hour 30 minutes

Place : Microsoft Teams (Online Session

Decoding Human Behaviour at Work

Date : Wednesday, 6th August 2025

Speaker : Mr. G. Praburam

Time : 03:00 PM to 04:15 PM IST

Place : Microsoft Teams

Session Highlights

- Why people actually quit—and why it's rarely just about money

- How people treat you based on what you tolerate and communicate

- The quiet power of recognition in shaping behaviour

- Real motivators behind commitment and performance

- Why people resist systems—and how to build trust

- Transitioning from managing work to leading people

PQ² Diagram – Importance and its Application

Trainer : Mr. Rajesh Aggarwal, Founder & Director – TechSense Engineering Services

Date : Wednesday, 23rd July 2025

Time : 09:30 AM to 06:30 PM IST

Duration : 1 Day

Platform : ALUCAST Training Centre, Pune

Topic Insights

- In-depth understanding of all elements of the PQ² Diagram

- Practical calculations with real-world HPDC examples

- Hands-on experience in constructing and applying the PQ² diagram

The 10 Misconceptions When It Comes to Becoming Digital in Your Operation

Date : Friday, 18th July 2025

Speaker : Mr. Christian Kleeberg, Founder & Managing Partner | RGU ASIA PTE LTD.

Time : 03:00 PM to 04:15 PM IST

Duration : 1 Hour 15 Minutes

Place : Microsoft Teams

Session Highlights

- Understanding the basics of digitalisation

- Common misconceptions and ways to overcome them

- Real-life examples from Indian shop floors

- Practical conclusions and industry-specific recommendations

Key Takeaways

- Foundational knowledge for digitalising metal casting operations

- Strategies to address and avoid common pitfalls

- Clear insights into what works—and what doesn't

- Actionable advice to help you begin, continue, or scale your digital efforts

Cost Management in Diecasting

Speaker : Mr. G. Praburam, Managing Director - Alubee Die Casters, Honorary Secretary - ALUCAST Bangalore Zonal Centre.

Date : Wednesday, 25th June 2025

Time : 03:00 PM to 04:15 PM IST

Duration : 1 Hour 15 Minutes

Platform : Microsoft Teams (Online Session )

Topic Insights

- Cost control through process optimization

- Efficient use of materials and resources

- Practical strategies for cost-effective production

- Real-world case studies from industry experience

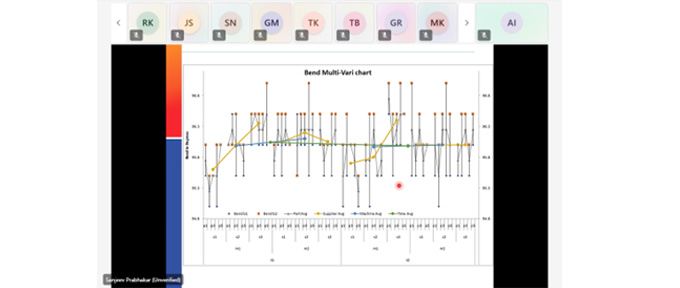

Data-Driven Approach to Problem Solving

Date : Friday, 20th June 2025

Speaker : Mr. Sanjeev Prabhakar, Vice President – R&D, Business Excellence & PE | Rockman Industries Ltd.

Time : 10:00 AM to 12:00 Noon

Duration : 2 hrs

Place : Microsoft Teams (Online Workshop)

Topic Insights

- Using facts and data to solve real-world problems

- Techniques to analyze processes and identify root causes

- Spotting bottle necks and applying creative solutions

- Building a data-driven mindset for problem resolution in the industry

Reciprocal tariffs by USA & CBAM policy by EU: Know all about the impact!

Trainer - Mr. Sudhakar Kasture, International Trade Consultant

Date : Friday, 30th May 2025

Time : 10:00 AM to 6:00 PM

Platform : Microsoft Teams

Topic Insights

- Export of Aluminium products from India (including castings)

- U.S. tariff on steel and Aluminium

- ESG Pillars - Environmental, Social & Governance

- ESG Frameworks and Standards

- What are the benefits of ESG

- ESG Reporting

- Carbon Border Adjustment Mechanism

- Possible remedies and how to improve competitiveness

PQ² Diagram

Date : Wednesday, 14th May 2025

Trainer : Mr. Sanjeev Prabhakar

Time : 10:00 AM to 12:00 Noon

Duration : 2 hrs

Place : Microsoft Teams (Online Workshop)

Topic Insights

- Why PQ^2

- Brief on the Physics of PQ^2

- Parameters of Interest in PQ² Analysis

- Machine

- Die Line (Tooling)

- Minimum Flow Rate

- Process Window of PQ²

Project Management Workshop

Trainer : Mr. Ravindra Kale – a distinguished industry expert, visiting faculty at leading B-Schools in India, and former General Manager at Mahindra & Mahindra

Date : Tuesday, 22nd April 2025 & Wednesday, 23rd April 2025

Time : 10:30 AM to 06:00 PM

Venue : Force Motors Limited, Training Centre, Mumbai-Pune Road, Akurdi - 411035

Duration : 2 Days

Content – Project Management

- Day – 1

- Overview of Project Management: Concepts and attributes of Project, Project lifecycle and stake holders, Scope and priorities

- Learning of Learning of Pre-feasibility, Specific Functional Studies (e.g., Facility Location study) & Feasibility culminating into preparation of DPR

- Project Life Cycle, WBS (Work Break down Structure)

- Project Planning: Time and cost estimates with AON and AOA conventions, Budget estimates, PERT network analysis for probabilistic projects

- Day – 2

- Network Analysis & Crashing Concepts

- Project Scheduling & Control: GNATT Chart

- Resources Allocation / Levelling: Minimizing the use of resources and working out the optimal plans with least resources without project delay

- Earned Value Analysis: 'S' Curve, Cost and Schedule performance

- Financial Appraisal: Debt Service Coverage Ratio (DSCR) & Interest Coverage Ratio (ICR), Non- Discounting Methods (e.g. Pay -Back Period, Accounting Rate of Return) & Discounting Methods (e.g. NPV, IRR, BCR)

- Project Organization: Different Structures, Role and responsibilities of Project Manager

FUNDAMENTALS OF ALUMINIUM CAST ALLOY - Webinar

Virtual Webinaron the ZoomOnline Platform

Wednesday 19th January 2022 from 03:00 pm To 04:30 pm IST

Aluminium Casters' Association (ALUCAST)®,Indiaorganized a Webinar on 'Fundamentals of Aluminium Cast Alloy' on Wednesday, 19th January 2022 from 03:00 pm to 04:30 pm IST.

The Webinar focused on three key areas :

- The Basics of aluminium

- Effects of Alloy Elements

- The Casting Properties of Aluminium.

Mr. N. Ganesan, Director – UltrasealIndia &Trustee – ALUCAST was the Expert Speaker for the Webinar. Mr. Ganesan, a graduate in Metallurgical Engineering from the University of Madras, has a total experience of 48 years in the field of Die Casting. He has a very long and wide experience in the field of Sand Die Casting, Gravity Die Casting, Low Pressure Die Casting, High Pressure Die Casting, Aluminium Alloy, Melting, Sand Core and Heat Treatment.

The Webinarreceived an overwhelming response from the industry. More than three hundred and fifty delegates from all over the country registered and participated in the event. The Webinar was FREE for the participants.

The Webinar was organized by the ALUCASTSecretariat. The Webinar incepted with the Opening Remarks and ended with the Closing Remarks from Ms. Kirti Ramdasi – Secretary,ALUCAST India. Mr. Rushikesh Bhange took care of the technical support for the Webinar.

ALUCAST HITACHI HIGH-TECH Webinar

Virtual Webinaron the Go To Webinar Online Platform

Tuesday 5th October 2021 03:00 pm To 04:15 pm

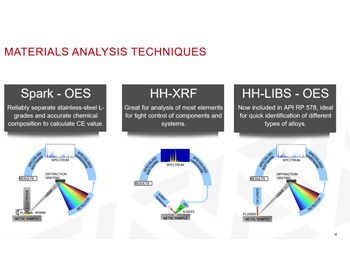

Aluminium Casters' Association (ALUCAST), India in association with Hitachi High-Tech Analytical Science, Oxford, UK and Hitachi High-Tech Analytical Science, R&D Centre of Excellence, Germany, jointly organized a Webinar titled 'MATERIALS ANALYSIS TECHNIQUES FOR ALUMINIUM INDUSTRY'on Tuesday 5th October 2021 from 03:00 pm To 04:15 pm. The Webinar addressed the analytical challenges faced by the primary and the secondary Aluminium Industries and the associated markets like Automotive and Scrap Recycling.

The Webinar received overwhelming response. About two hundred delegates from all over the country registered and participated in the event. The Webinar was free for the participants.

Mr. Dhaval Rathod, Business Development Engineer, Hitachi High-Tech, Indian Sub-continent presented brief information about Hitachi High-Tech's market presence in the area of material analysis instruments and equipment. Mr. Frank Theuws - General Manager for Global OES Distribution, Hitachi High-Tech Analytical Science based in Germany was the Chief Speaker for the Webinar. With over 30 years of global experience in Optical Emission Spectroscopy, Frank has extensively travelled in Asia Pacific, China and India understanding markets, customer needs and future analytical requirements. He has also previously worked in the applications and method development teams and has astute knowledge of the technology in this field of metal and non-metal industry. Mr. Frank spoke about the current global scenario of the primary and the secondary Aluminium Industry, fluctuating material prices and the challenges faced by the Industry with respect to the quality and the inspection and analysis of the quality of the materials.

The Webinar was organized by the ALUCAST Secretariat. The Webinar incepted with the opening remarks and ended with the closing remarks from Ms. Kirti Ramdasi – Secretary ALUCAST, India. Ms. Neha Karnik – Head, Marketing Communications, Hitachi High-Tech Analytical Science, Asian Markets, Singapore coordinated the entire programme.

ALUCAST-SLM Solutions Webinar

Virtual Webinar on the GoToWebinar Online Platform

26 August 2021 03:00 pm to 4:15 pm India

Aluminium Casters' Association (ALUCAST) in association with SLM Solutions Group AG, Germany and SLM's authorized partner in India - ARK Infosolutions Pvt Ltd, jointly organized a Webinar titled 'HOW DIE CASTING INDUSTRY CAN BENEFIT FROM 3D PRINTING' on 26th August 2021 from 03:00 pm To 04:15 pm.

The Webinar addressed the current challenges in Die Casting Industry with focus on more efficient and cost-optimized production with the help of 3D Printing Technology. The benefits of increased service life with optimized tempering, process optimization to reduce overall cycle times and 60% shorter cooling time through internal cooling channels was discussed.

The Webinar contents included introduction to the SLM Solutions Selective Laser Melting Technology, and presentation of the 3D Printing process. This was followed by discussion on increasing productivity and quality with AM tooling insert,improving time to market, reducing cost for prototype and low volume production.

The Webinar received overwhelming response. Around two hundred delegates from all over the country registered and participated in the event. The Webinar was free for the participants.

Mr.RalfFrohwerk, Global Head of Business Development SLM Solutions Group AG & Mr.Kaushik Deshikan Shettalur, Applications Engineer, SLM Solutions India were the speakers for the Webinar. Ralf Frohwerk manages the global business development at SLM Solutions Group AG and is based out of Germany.Kaushik Deshikan Shettalur is responsible for pre and post sales application support and machine &application training for the customers in India and is based out of Bengaluru. Kaushik is a Factory Certified Engineer for installation and troubleshooting of SLM machines.

The Webinar was organized by the ALUCAST Secretariat. Kirti Ramdasi – Secretary ALUCAST, India and Naresh Mettugari – SLM Solutions coordinated the entire programme.

ALUCAST NADCA Series of Webinars

Conducted on Zoom Platform : April-May-June 2021

Topics : Productivity Improvements, Mechanical Properties of Die Cast Alloys & New Technologies in Die Casting

ALUCAST NADCA Series of Webinars has elicited a tremendous response with nearly one hundred delegates from all over the country registering to listen and interact over the several sessions.

Sessions were conducted by Dr. Steve Midson. Dr. Steve Midson is empanelled with NADCA. He has authored books on die casting dies, with special emphasis on improving die life. He conducted two- & three-day training programs at different Centres (Pune, Delhi, Bengaluru& Chennai) in 2017 and 2019, on behalf of ALUCAST. Dr.Midson is associated with research groups in USA and China (where he is also a consultant).

Topics covered include Productivity Improvements, Mechanical Properties of Die Cast Alloys & New Technologies in Die Casting. Details are given below.

Mechanical Properties of Aluminum Die Cast Alloys

- The objective of this 2-part webinar series is to document in an organized manner the large amount of data has recently been published by NADCA regarding mechanical properties of conventional aluminum die castings.

- The webinar series will cover the following information:

- Document handbook mechanical properties

- Describe the impact of chemical composition on properties

- Discuss the change in die cast mechanical properties over time

- Show the impact of porosity and defects on mechanical properties of die castings

- Impact of changing composition within the specification range for alloy 380

- Properties of low-iron, strontium-modified aluminum die castings

- Heat treated properties of conventional and low-iron aluminum die castings

- Mechanical properties of cast-to-size samples versus samples cut from actual die castings

Productivity Improvements

- The objective of this 2-part webinar series is to describe methods to allow the production of more castings per hour, not only looking at faster cycle rates, but also by minimizing downtime.

- The webinar series will cover the following information:

Die related- Improved thermal control

- High thermal conductivity die materials

- Improved cooling

- Bi-metallic cores

- Better control of cooling water

- Low temperature casting process

- Ladling while die is still open

- Minimize lubricant spraying

- Changing ejection criteria

New Technologies in Aluminum Die Casting

- The objective of this 3-part webinar series is to documents recent advances in aluminum die casting technology

- The webinar series will cover the following information :

Part 1- Advances in aluminum die casting alloys

- High integrity die casting processes

- Additive manufacturing of dies

- Advances in die materials

- Pulsed spray

Sponsors for the event included Rockman Industries Ltd., Sunbeam Lightweighting Solutions Pvt. Ltd., Jaya Hind Industries Ltd, and Sundaram Clayton Ltd.

Over 100 registered and took part in the event while at remote locations, teams from the supporting companies viewed the proceedings on large screens in conference rooms and halls. Feedback received from participants was very good.

Mr. Rushikesh Bhange and his team from ALUCAST managed the platform and conducted the event. The Advisory Committee to the event included Ms. Kirti Ramdasi, Mr. Ganeshan Natarajan& Mr. Niranjan Toraskar.

ALUCAST-NADCA Training Courses 2019 : ALUCAST-NADCA Training Courses in Die Casting

The ALUCAST – NADCA training sessions were organized by Aluminium Casters' Association of India (ALUCAST) and conducted by faculty (Instructors) from NADCA (Dr.Stephen Midson for Process and Dr. R. Allen Miller for Design).

They were conducted at 4 venues- Pune, Chennai, Bengaluru and Gurgaon between 09 August 2019 and 30 Aug 2019 (3 days at each city) with both streams running concurrently in two separate halls at the same venue.

The Topics covered were designed to fulfil the training needs of most die casters, dealing with PROCESS and DESIGN streams. At Gurgaon, a successfully completed case study was presented by Mr. Sandeep Tandon of DST Industries during the session.

All the participants were given certificates of participation by the respective Faculty members.

Training Programs at Pune in July 2018

The second week of July 2018 was a busy period at the Pune based ALUCAST office. Two training programs were conducted , the first on 9 July titled " Manufacturing Process Audit using VDA 6.3" followed by " Metal Flow & Solidification Pattern of Metal Inside die : Simulation Using Computer:" on 12 July.

The 15 and 20 delegates who attended the two one-day programs respectively were a satisfied lot. Most of them said they came to the programs with certain expectations and these were fully met . They appreciated the sessions where case studies of casting samples carried by the delegates were taken up in open sessions and the faculty guided the delegates themselves toward finding solution to problems. They wanted more such case studies analysed in future programs.

Mr. Chandrasekhar Deokar, Faculty for the Quality Management topics, impressed the delegates with his flowing style of rendering a dry subject into an interesting session. The sessions were interactive and delegates were given ample opportunities to speak out. Mr. Rajesh Aggarwal, Faculty on Die Design, put the delegates at total ease with his characteristic way of making difficult points easy to understand. The delegates appreciated the sessions where case studies of casting samples carried by the delegates were taken up in open sessions and the faculty guided the delegates themselves toward finding solution to problems. They wanted more such case studies analysed in future programs.

The delegates had good words for the training facilities , hospitality and the program management and co-ordination. Most have recorded that they would encourage their collegues to attend ALUCAST Training Programs.

Corporate Training Program at Eaton Technologies Pvt.Ltd.

ALUCAST successfully conducted a 4-day training course on Die Casting Process and Die Design, attended by 20 Engineers of Eaton Technologies Pvt. Ltd., Pimpri, Pune. The Engineers are part of the team manning the Supplier Quality Assurance, responsible for sourcing documentation, inspection and clearance of die cast aluminium parts which are used in the Hydraulic Systems of Tractors etc. John Deere is one of the major OE customers, who uses these Hydraulic Systems in their Tractors. Considering the nature of work of the target audience, ALUCAST prepared a complete new set of topics to be covered and the course material, copies of which were given to the trainees before the sessions started. The in-house training sessions were spread over four working days 21-22 March and 28-29 March 2018.

Mr. R. A. R.Prasad, Mr.N.Ganesan, Mr. Rajesh Aggarwal and Mr.N.V.Toraskar were the faculty members. The course contents, methodology and open house sessions were appreciated by all the trainees, who also said that such sessions should be repeated at least once every year so that the Engineers are up to date.

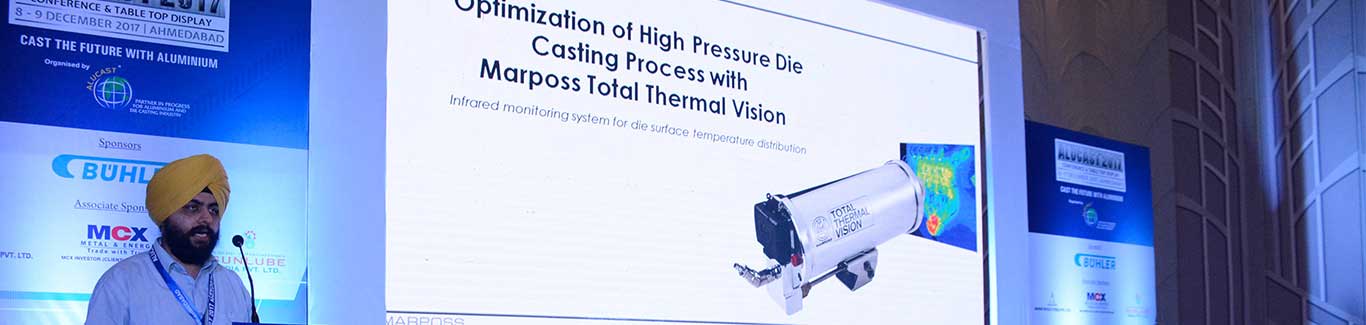

ALUCAST-NADCA Training Program 2017

The ALUCAST – NADCA training sessions organized by Aluminium Casters' Assocition of India (ALUCAST) and conducted by faculty (Instructors) from NADCA concluded with the end of day 3 (7 Sep 2017) of the three day sessions at Hotel Chancery Pavilion , Bengaluru. Right from the opening session at the Hotel Pllazio, Gurgaon,on 28 – 29 – 30 Aug 2017, through the three days (1 – 2 – 3 Sep 2017) at the Hotel Sheraton, Bund Garden, Pune, and finally the three days (5 – 6 – 7 Sep 2017) at Hotel Chancery Pavilion, Bengaluru, the entire program was executed without a hitch and with clockwork precision, thanks to the efforts of the Office Bearers and other members of the ALUCAST teams at the three Zonal Centres, the two Instructors and the hotel staff.

Response from the die casting industry was overwhelming. A total of over 150 delegates attended the Training Sessions, with each of the three venues registering 50 or more delegates. Maruti Suzuki lead the pack with 18 delegates, Jaya Hind Industries, Endurance Technologies and Cummins Group followed with 8 delegates each, BOSCH and EATON with 5 each, and HMSI, India Yamaha, Sunbeam Auto were firms who sent 4 delegates each, reflecting participation from all regions of India which have high concentration of die casting units.

The design and contents of the Training sessions were conceived and developed by Mr. R. A. R.Prasad, Advisor (Technical), ALUCAST, with inputs from the two Instructors, Dr. Steve Midson and Dr. Allen Miller, who were hand picked by NADCA from a large pool of Instructors at NADCA. The two most important aspects of die casting technology, namely "PROCESS" and "DESIGN", were tackled by Dr. Midson and Dr. Miller respectively.

As many as 102 delegates opted for Stream 1 (PROCESS), handled by Dr. Steve Midson, and 51 delegates opted for Stream 2 (DESIGN), handled by Dr. Allen Miller. All the sessions were highly inter active and the Instructors fielded the questions with aplomb, to the full satisfaction of the delegates. However, a view expressed by many delegates, as per notings in the Feed back forms, was that they would welcome presentation of actual Case Studies, to supplement the text given as Course Material.

Handing over Certificate of participation to all the delegates, Dr.Midson remarked that he found substantially greater awareness and application of die casting technology amongst delegates attending this years' sessions, compared to four years ago. (Dr. Midson was a faculty during similar sessions held during November 2013 also).

Training Program TP-1603 at Pune

A two day training program titled "Engineering Die Casting Dies in Sync with Die casting Process" was held at the Training Hall, Amar Neptune at ALUCAST office, on 23 and 24 June 2016. Among the thirteen delegates who attended was also a student of NTTF, Bengaluru. All the delegates were appreciative of the course content, training arrangements and particularly the methodology used by the faculty. Suggestions received by way of feedback were a) course duration to be at least 50% longer, so as to allot more time for detailed explanations) More visuals/video films to be use to explain casting simulation and die casting process.c) Pictures/Photographs used to illustrate process/simulation to be in color.(if this is not possible, soft copy to be given in pendrives)

ALUCAST gave 50% concession on course fees for bonafide students.

Training Program at BATS (Buher ALUCAST Training School), Bengaluru

A two day training program was conducted at BATS, Attibelle, Bengaluru on 8th and 9th Feb 2016. The program was attended by 22 delegates from Bengaluru Zonal Center. This training program also includes hand-on training on Buhler Ecoline 53 machine. The faculty was Mr.P.Sukumaran Menon, Consultant, 4M Dynamiks.

Another such training program is planned in the month of April 2016 on 18 and 19 April 2016.

Training Program (TP-3 ) held at Pune

This training course was designed and specially aimed at entry level engineers in quality control, quality assurance and metallurgists in Aluminium foundries, personnel responsible for development and procurement of Aluminium castings outsourced. Also of interest to Engineering Degree and Diploma Students in Metallurgy/Mechanical Engineering. The Course covered Introduction to Aluminium as a versatile metal, effect of alloying elements, classification and use of Aluminium Alloys in some detail. Metallurgy and In-House preparation of common casting alloys. Post Casting Operations on Aluminium Castings.

Effect of Heat Treatment on physical properties of Aluminium alloy and why Heat Treatment is classified as a "special process." Certificates of participation in the training program were awarded to the delegates.

Training Programme at Pune

The First Training Programme(TP-1) was conducted by ALUCAST in its own premises in the newly inaugurated fully equipped training Hall at Baner Road, Pune. Mr.VishwasKale, Former Trustee and Senior Member of ALUCAST, Manging Director, Vijayesh Instruments Pvt.Ltd. inaugurated the Programme. More than 20 delegates attended the training programme. The Programme was aimed at the middle management personnel in the diecasting industry - the Process owners, persons authorized to make changes (Shop floor Engineers, QC Engineers, Die design engineers, Tool room engineers.)

The Course was designed by keeping in mind the need of the hour that Indian Die casters need to refresh fundamentals and have systematic approach in Process or problem solving rather than fire fighting and working on hunches.

Emphasis was given on the analytical part of die casting die in relation to die casting process to explain clearly the "WHY", and not only the "WHAT" and "HOW" of die design and casting process but also to inculcate mutual respect and appreciation of compulsions of die design engineer and process engineer. Casting defects and fundamentals of process and their correlation, simple problem solving techniques was also covered.

The two Faculty members, Mr. Rajesh Aggarwal, a National(ALUCAST) and International(NADCA) Award winning designer and Senior GM Casting Product Development Center and Tool Room at Endurance Technologies and Mr.Viviek Joshi, Senior GM Quality and Systems at JayaHind IndustriesLtd. conducted the training course setting new standards for clarity of expression and satisfying every single query from the delegates.

Certificates of participation in the training programme were awarded to all the delegates. A brief on various courses to be conducted by ALUCAST in future was also given to the delegates.